- What is supply chain transparency and why is it important

- Why is not all data created equal

- How to achieve transparency with accessible quality data

In today’s global market, supply chain transparency has become an essential requirement for companies. Businesses do not only want to ensure the quality of their products and services. They are also facing increased pressure to maintain high standards of social and environmental responsibility. Supply chain transparency is the key to achieving both these goals. It allows companies to track and report on their supply chain activities, meet regulatory requirements, and ensure that their products are ethically sourced and sustainably produced. In addition to the advantages for society and the environment, transparency has benefits for businesses as well. By keeping an eye on every stage of the supply chain, businesses see possible disruptions early and take proactive measures to reduce them.

However, achieving absolute supply chain transparency is not an easy task. One of the main challenges companies face is poor-quality data in the logistics industry. Inaccurate or incomplete data can lead to inefficient operations, increased costs, and even reputational damage due to customers’ dissatisfaction.

In this blog post, we will explore the problem of poor data quality in the logistics industry, and look at how digital logistics platforms can help to improve supply chain transparency.

What is supply chain transparency and why is it so important?

Supply chain transparency refers to the degree of openness and visibility companies have in monitoring and auditing their entire supply chain. It involves a holistic view of each step in the purchasing, production and supply process.

While visibility is a crucial component of transparency and provides insights into the operations from the company’s POV, transparency allows a more comprehensive view of the supply chain. It includes practices and processes of suppliers and partners. A transparent supply chain implies open access to data, communication, and accountability in operations. External stakeholders are able to understand and evaluate company information, decisions, and outcomes.

Such transparency is essential to ensure that products are manufactured ethically and sustainably and that labor rights are protected. Consumers and investors are increasingly demanding these insights. Recent legislation, like the German Supply Chain Due Diligence Act, even prescribes transparency by law.

But despite (or perhaps because of) external pressure to disclose their activities, companies also benefit from greater transparency:

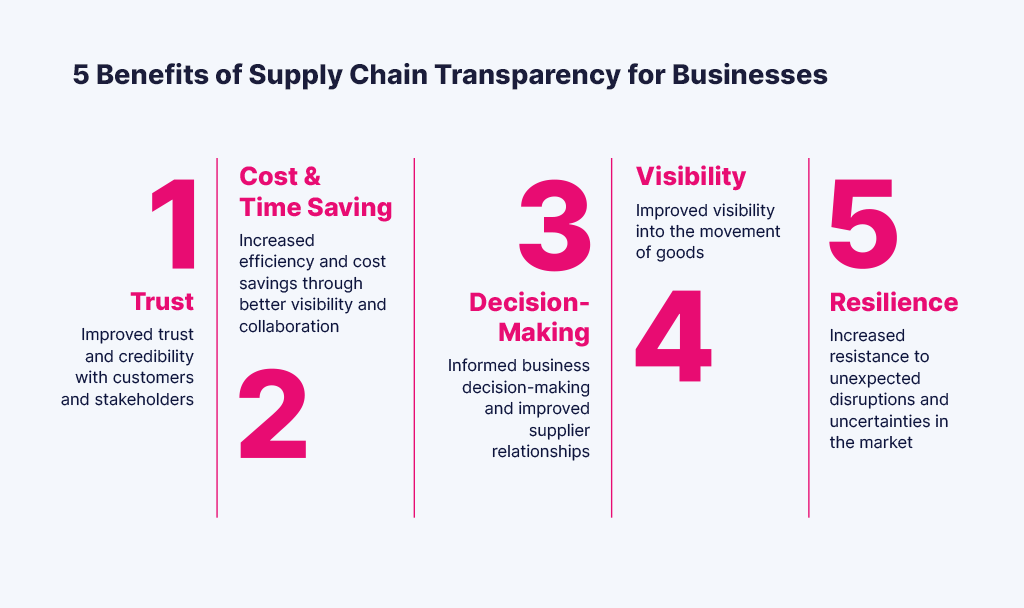

5 Benefits of transparent supply chains for businesses

Supply chain transparency is a business strategy that has numerous benefits for companies.

- Trust: Transparent supply chains improve trust and credibility with customers and stakeholders. A company that invests in supply chain transparency can communicate its commitment to ethical practices. Customers receive a clear understanding of the origin of the products. For example, apparel company Patagonia is transparent about the factories where its clothes are made and provides information on the materials used, encouraging trust and loyalty among its customers.

- Cost & Time Saving: Supply Chain Transparency increases efficiency and cost savings through better visibility and collaboration. By having greater transparency in their supply chain, companies can identify bottlenecks and inefficiencies, and work collaboratively with suppliers to optimize processes. For example, Walmart implemented a blockchain system to track the origin of food products, reducing the time and resources needed to trace products back to the source.

- Decision-Making: It supports informed decision-making and improves supplier relationships. Supply chain transparency allows companies to make informed decisions about which suppliers to work with, based on factors such as performance, ethical practices and sustainability. By promoting transparency, companies can also build stronger relationships with their suppliers, encouraging collaboration and innovation. For example, Adidas uses a tool to monitor suppliers’ working conditions, providing data for informed decision-making and building long-term relationships.

- Visibility: On an operational level, it provides visibility into the movement of goods. Supply chain transparency allows companies to track the movement of goods in real time, reducing the risk of lost or delayed shipments. This can help companies to manage inventory better and reduce waste. For example, Zara uses RFID technology to track the location of garments in their supply chain, providing real-time data to optimize inventory management.

- Resilience: Last but not least, transparency leads to supply chain resilience. When companies have greater visibility and transparency across their supply chains, they are better equipped to anticipate and respond to disruptions. At the beginning of the Covid-19 pandemic, a Hanseatic trading company, selling a broad range of items from canned goods to decorative items, stationery, textiles, and electronics, had to import several million face masks as quickly as possible. They did this during a time period framed by a tense global trade situation. With Forto, the company was able to access an advanced digital platform that allowed them to make use of smart data to track shipments online and in real-time. With improved shipment traceability, the company was able to tightly manage production to satisfy demand while managing exceptions and inconsistencies online with the help of built-in communication and activity tracking features.

The benefits of supply chain transparency are evident.

However, there is a big BUT.

All of these insights need data. And while companies understand that data is important and there are many sources of data to draw from compared to just a few years ago, data does not always equate to transparency.

The Problem: not all data is created equal

To benefit from supply chain transparency, companies first need to gather data. In the digital age, data has become one of the most valuable assets to businesses. However, not all data is created equal. Some data may be more useful than others in terms of providing insights and helping businesses make decisions. This is why companies need to understand the difference between high and low-quality data and how to use it effectively.

The complexity of modern supply chains requires companies to have access to more data than ever before. However, access to data does not necessarily equate to transparency. There are several problems with the data that companies receive today, which can cause a wide range of problems, including instability, unpredictability, delays, additional costs, and poor customer service.

Common issues with data

- Source issues: One of the main issues with supply chain data is that it comes from a variety of different sources and media. This can lead to inconsistent and siloed information. The fragmented nature of the ecosystem also results in the fragmentation of data. Email, API, EDI, CSV files and the occasional phone call – supply chain professionals deal with many different stakeholders and data sources which can lead to too many data pools.

- Format issues: Different sources often present data in different formats, making it challenging to integrate and analyze the information. As a result, companies can find it demanding to make sense of the data they receive.

- Structure issues: Closely liked to the format issue is the structure issue. Supply chain data is often raw and unstructured, which means it is not organized in a way that is easy to interpret or analyze. For example, data in a CSV file is unstructured. It is simply a list of values separated by commas, with no inherent structure. Companies do not have the time and resources to collect and clean data from different sources, making it difficult to use the information effectively.

- Accuracy issues: Inaccurate data is one of the biggest problems in supply chain operations. Inaccuracies can result from human errors, data drift, and data decay. This can cause significant issues, leading to missed opportunities or wrong decisions. For example, the 2016 Hanjin Shipping bankruptcy left 90 ships stranded at sea, with billions of dollars worth of cargo on board. Inaccurate data on the location and status of the ships made it challenging for companies to determine the location of their goods. This led to delays and additional costs as they tried to reroute their shipments.

Another problem is often the cost and effort to collect this information, structure it, and process it in such a way that it brings added value. Permanent monitoring and auditing of the supply chain activities can be expensive. Businesses may have difficulties allocating the necessary resources. Thus, expert personnel dedicated to supply chain transparency are needed. However, many companies don’t have data scientists or business intelligence departments that are dedicated to this task only. Medium-sized companies in particular often have to create this capacity first or outsource it.

The Solution: easily accessible high-quality data

To achieve supply chain transparency, companies need easy access to dependable data. However, the level of data quality necessary for transparency is often rare in the logistics industry. Companies can rarely “pick and chose” the quality of which data is provided. What they can choose, though, is a partner that provides them with easy-to-access, pre-structured and meaningful data insights. This enables them to focus on informed decision-making instead of converting endless CSV files.

Step 1: Understand what constitutes high-quality data

Companies need reliable, accessible, and actionable supply chain data that provides real insights. By addressing the problems associated with supply chain data, companies can operate effectively and efficiently and deliver the best possible service to their customers.

In terms of quality, companies should look for:

- Accuracy – Is the data correct in every detail?

- Completeness – How comprehensive is the data?

- Reliability – Does the data contradict other trusted resources?

- Relevance – Do you really need this data?

- Timeliness – How up-to-date is the data? Can it be used for real-time reporting?

Example: An example of the importance of accurate data is the Cargo Ready Date (CRD) in sea freight shipping. Accurate, reliable and timely dates are crucial for shippers. The CRD refers to the time when goods are ready for shipment and is therefore a critical factor in managing supply chain activities such as transportation, inventory management, and production planning.

Accurate CRDs allow stakeholders to plan and allocate resources efficiently. Shippers can reduce lead times and prevent delays that lead to additional costs or customer dissatisfaction. Additionally, by sharing accurate CRDs with suppliers, carriers, and customers, supply chain partners can improve collaboration and build trust. This leads to a more transparent and efficient supply chain.

Step 2: Invest in data accessibility and a single source of truth

However, even the best data – fulfilling all above mentioned criteria – is only worth half if it’s scattered around different data pools and systems. Having one easily accessible single source of truth is helping to create supply chain transparency.

Easy access to data supports businesses, especially in terms of sustainability and transparency goals. It allows companies to measure, manage, and report on their environmental, social, and governance (ESG) performance. By having a central repository for sustainability data, businesses can identify areas of improvement. ESG progress gets visible and can be communicated to stakeholders. This helps to enhance transparency, build trust, and maintain a competitive edge in an increasingly sustainability-focused market.

High-quality data and easy access to this data give companies the needed business-relevant insights for their supply chain operations. With this level of visibility, companies can improve their decision-making, enabling them to real supply chain transparency.

Step 3: Combine high-quality data and accessibility

As mentioned, many companies can’t choose the quality, timeliness or accuracy of data they receive from third parties. SMEs also often can’t clean up the data themselves downstream. The various media and data sources from which the information comes make it even more difficult for companies to get reliable supply chain transparency. But, there are already solutions that do just that for transportation data. Logistics platforms not only aggregate data from multiple sources, but intelligent algorithms also improve the quality of the data without requiring company employees to spend countless hours cleaning, processing and interpreting it themselves.

For example, Forto works with over 100 ocean, air and road transportation companies, customs brokers and terminals through direct integration and specialized transport data aggregators. As a result, customers receive the required high data quality through a combination of automated and manual data checks. The clean data is passed to SHIP (Forto’s booking and visibility platform) and the TMS to give customers a clear and comprehensive view of the entire transportation process.

This data remains stored in one place, is easily accessible and unambiguous to interpret, and can be used at any time by logistics and supply chain managers for quick decision-making.

Conclusion:

Transparent supply chains are becoming increasingly important for companies to maintain trust and credibility with customers and stakeholders. With better transparency, companies can achieve greater efficiencies and cost savings. All, while promoting ethical and sustainable practices throughout the supply chain. In addition, transparent supply chains can support informed decision-making and arm companies against future external shocks and disruptions.

However, it is important that the data provided is of high quality and easily accessible to enable effective analysis and decision-making. Companies must first understand what data quality requirements are and ideally store and access this data in a central location. This may seem trivial at first, but evaluating and processing the data can become a mammoth task, especially for SMEs. However, this is the first important step that companies have to take in order to achieve long-term supply chain transparency.

Finally, transparent supply chains enable companies to establish themselves as responsible members of society while reaping the benefits of improved supply chain efficiency, cost savings and customer confidence. A win-win situation for all sides.

Digital logistics platforms: A solution for improved data quality

Supply chain data is the primary source of information used to improve visibility, and visibility is required for transparency. Transparency leads to resilience and operational excellence. For companies looking to gain more visibility into their supply chain data and make better business decisions based on meaningful insights, digital logistics platforms offer the right solution.

At Forto, we prioritize transparency and efficiency in supply chain operations

We believe that all companies profit from transparent supply chains and offer the visibility through data that is needed to achieve that transparency.

Our technology solution provides our customers with superior visibility at the most crucial stages of a shipment’s journey. For example, our platform SHIP helps companies to stay informed and prepared with smart insights along the shipping process like CRD notifications.

By improving logistics information availability, accuracy, and timeliness and encouraging cross-functional collaboration, we reduce uncertainty, errors, and disruptions, simplifying the planning and execution of logistics activities for our customers.

Moreover, our platform solution provides companies with transparency over the environmental impact of their transportation activities. Emission reports for all transport activities with Forto are accessible at one single source of truth.

Want to learn more about how we help with supply chain transparency?

Schedule a demo and subscribe to our newsletter to get the latest product updates.