The past years have been tumultuous for businesses around the world. A global pandemic. An unexpected war in the middle of Europe. Supply bottlenecks. A ship blocking the Suez Canal causing mass shipping delays. Port congestions. A worldwide recession that continues to this day. These events have made it clear that the clockwork of global supply chains is both important and fragile.

As a result, the once-niche topic of supply chain resilience has graced news headlines and moved to the top of CEOs’ agendas.

In this post, we will explore three key lessons that the past years have taught us about supply chain resilience and discuss how businesses can be better prepared for future disruptions.

What Is Supply Chain Resilience and Why Is It Important?

Supply chain resilience refers to an organization’s ability to respond to unforeseen events or circumstances in its supply chain to sustain its business processes and operations. This can include the ability to minimize supply disruptions, quickly adjust the supply chain, and minimize the impact of crises.

Unforeseen disruptions in the supply chain can paralyze entire companies. Imagine a retailer not receiving the new summer collection on time for store availability, or a car manufacturer not being able to roll out their newest model because of an important key component shortage.

Having a resilient supply chain is important because it helps companies ensure their business processes stay up and running, increase customer loyalty and maintain competitiveness by ensuring that products and services are delivered on time and reliably. In short: Supply chain resilience is a guarantee of business continuity and success.

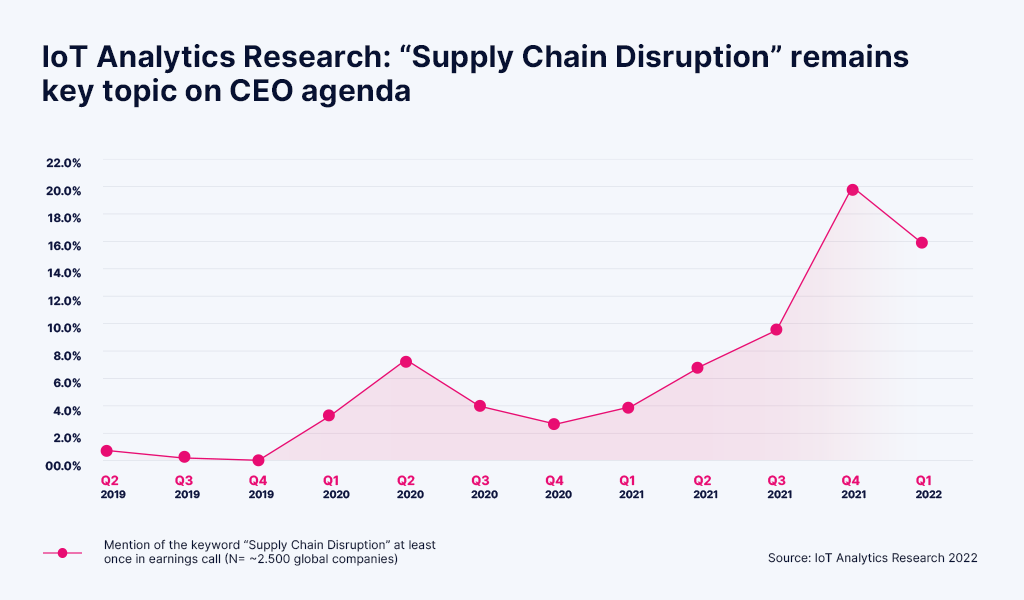

In recent years, the topic of supply chain resilience has become increasingly prevalent, moving higher on the C-Level agenda. IoT Analytics, a global provider of market insights and analytics, researched over 3.000 companies and visualized what topics and conversations CEOs prioritize. According to the research, only 0.1% of CEOs talked about supply chain disruption before the pandemic. Naturally, the topic rose during the first COVID-19 wave and after a brief decrease, the topic picked up steam once more in the second half of 2021.

Since then, the conversations about supply chain disruptions are on an all-time high. To mitigate disruptions many executives turned to seek supply chain resilience strategies. Discussions about supply chain resilience are here to stay, so it’s important to look at the lessons the past has taught us and draw conclusions for the future. Here are the most valuable lessons.

Lesson 1: The Importance of Diversifying Your Supply Chain

One of the most important lessons that the past year has taught us is the importance of supply chain diversification. When COVID-19 first hit, many businesses were taken by surprise. Sudden shutdowns of factories and other production facilities in China caused widespread shortages of goods and materials. Many businesses were forced to scramble to find new suppliers on short notice.

The need for diversification played an important role in investigating new production sites and testing out alternate trade routes and transportation systems. The March 2021 Ever Given Suez Canal blockage resulted in traders having to reallocate goods that would otherwise be delivered by sea to aircraft. Russia’s attack on Ukraine, on the other hand, made the previously little-noticed Middle Corridor more attractive for freight transport by rail.

The lesson is clear: having a diverse and geographically dispersed supply chain can help to mitigate the risk of disruptions. By diversifying your supply chain with both, alternative transport options and suppliers, you can make your business more resilient. Knowing how to leverage alternative trade routes and transport modes, you can reduce your dependence on geographic regions, which can keep your business running. At the same time, having multiple, geographically dispersed suppliers makes your business more agile.

Lesson 2: The Importance of Strong Relationships

Another crucial lesson is the importance of strong relationships along the whole supply chain with both, suppliers and service providers. Reducing one’s dependence on singular suppliers – like suggested in Lesson 1 – does not mean in any way tearing up relationships with said vendors. On the contrary, new and old relationships should be built on an even stronger foundation of trust.

When the pandemic first hit, many businesses found themselves at the mercy of their suppliers, who were struggling to keep up with demand and facing their own disruptions. This was true not only for suppliers of raw materials and goods but especially for transport service providers. Reliable transportation providers ensured continuity while providing backup plans and creative solutions through lockdowns, closed borders, congestions, and bottlenecks. Many transport companies made the impossible possible in difficult times.

The lesson here: having strong relationships with your suppliers can help to mitigate the risks of disruptions caused by unpredictable events. By building strong relationships, you can ensure that all links within your supply chain will work with you to find solutions to any problems that may arise and that they will prioritize your needs in times of crisis. This can ensure that your business is better prepared to weather unpredictable disruptions.

Lesson 3: The Importance of Supply Chain Visibility

The past few years have shown that digital tools are a must-have for any company looking to make its supply chain more flexible and responsive to unexpected changes. As these tech solutions mature, the adoption of technology such as Machine Learning/Artificial Intelligence, IoT tracking, and cloud services gives companies in the space a real edge over their competition.

A 2022 McKinsey survey of global supply chain leaders found that more than 90% of respondents reported investing in digital supply chain technologies last year. Those who focused their efforts on boosting end-to-end visibility were twice as likely to say that they had no difficulties with the effects of supply chain disruptions in 2022.

Leaders seeking to build digital-first supply chains should focus first on achieving end-to-end visibility. Global supply chains are highly complex, with dozens of different stakeholders and touchpoints, each of which could have unique systems and processes in place. Mapping them end-to-end gives companies much-needed visibility. This kind of visibility builds resilience into the supply chain by detecting and managing risks early on, supporting cost management, increasing efficiency, and enabling better-informed decisions.

But here’s the thing, visibility is only as good as the data it’s working with. If you’re using crummy data, you’re not going to get a whole lot out of your visibility tools. That’s why it’s so important to make sure you’re using accurate, accessible, and timely data. Only then can you really get a handle on what’s going on in your supply chain and take steps to protect your business.

The lesson here: It’s clear that investing in supply chain visibility is a no-brainer for organizations. Still, companies need to make sure they’re getting high-quality data out of it to build long-term resilience.

Conclusion: Lessons Learned

Supply chain resilience is becoming increasingly important in today’s fast-paced business environment and it’s essential for companies of all sizes to prioritize it in order to survive and thrive in the future.

By proactively building resilience into supply chains, businesses can ensure that they are better prepared to respond to disruptions caused by events such as natural disasters, geopolitical instability, health crises and pandemics, labor strikes, supply and transport congestions, and other unforeseen events. Having contingency plans in place and putting supply chain resilience as a strategic imperative can weather companies from disruption storms.

Diversifying supply chains, building strong partnerships along the whole supply chain, and investing in data and digital visibility are the way forward to equip organizations against future disruptions.

How Forto can help

Transportation is a key component of supply chain resilience. Forto helps companies to be more agile by diversifying their transport modes. Forto offers access to different transportation modes, such as air, sea, rail, and multimodal options. Multiple options allow businesses to optimize their supply chain for cost and efficiency. This can help to ensure flexible on-time delivery at the lowest possible cost.

As a digital freight forwarder, Forto understands better than anyone the importance of data in maintaining resilient supply chains. Forto uses advanced analytics, proprietary algorithms, and intelligent automation to filter, analyze, and structure data to become insights. With our digital platform, supply chain leaders can make better-informed decisions at a tactical and strategic level.

Build strong relationships through performance data across your supply chain. Forto empowers you not only to maintain and boost collaboration with your transport and procurements partners, with a platform that makes communication across supply chain teams easier.

Last but not least, Forto engages the most ambitious and seasoned logistics professionals whose freight forwarding and transport knowledge are super-charged with the help of a unique, proprietary technology – so that we can support you as a reliable and dependable partner at all times.

Want to learn more? Contact us